How to Fix a Vacuum Leak (Step-by-Step)

How to Fix a Vacuum Leak (Step-by-Step)

A vacuum leak is unmetered air entering the engine after the mass airflow (MAF) sensor (or bypassing expected airflow paths). The result is usually a lean condition, unstable idle, hesitation, and sometimes a check engine light. This guide walks you through a practical, repeatable process to find the leak, confirm it, repair it properly, and verify the fix.

Safety note: Work on a cool engine when possible. Keep hands, clothing, and tools away from belts/fans. Use sprays carefully and never near hot exhaust components.

Common symptoms of a vacuum leak

- Rough or high idle, idle surge, stalling at stops

- Hesitation or poor throttle response

- Hissing/whistling sound from engine bay

- Check Engine Light (often lean codes like P0171/P0174)

- Fuel trims significantly positive on a scan tool (engine adding fuel to compensate)

Tools and supplies

Basic

- Flashlight

- Nitrile gloves, safety glasses

- Pliers (for spring clamps)

- Screwdrivers, small socket set

- Shop towels

Diagnostic (pick what you have)

- OBD2 scanner that shows live data (fuel trims / STFT / LTFT is ideal)

- Smoke machine (best method if available)

- Carb cleaner or brake cleaner (use sparingly)

- Soapy water spray bottle (for some external checks)

- Hand vacuum pump (optional, helpful for testing certain components)

Repair supplies

- Assortment of vacuum hose (common sizes vary by vehicle)

- Replacement elbow connectors / tees (plastic fittings get brittle)

- Hose clamps (spring or worm clamps)

- Intake boot / duct tape is not a repair—replace the boot if cracked

- Replacement gaskets if leak is at a sealing surface (throttle body gasket, intake manifold gasket, etc.)

What counts as a “vacuum leak” (and what doesn’t)

Vacuum leak sources:

- Cracked vacuum hoses, elbows, tees

- Intake boot cracks (between airbox/MAF/throttle body)

- Loose clamps

- Leaking intake manifold gasket

- Throttle body gasket leak

- Brake booster hose/check valve leak

- PCV hose/PCV valve gasket leak

- EVAP purge valve stuck open (acts like a vacuum leak at idle)

Not a vacuum leak:

- Dirty throttle body causing sticky idle control

- Failing ignition coil/misfire (can mimic lean behavior)

- Fuel delivery problem (can trigger lean codes without unmetered air)

Step-by-step: Find and fix the leak

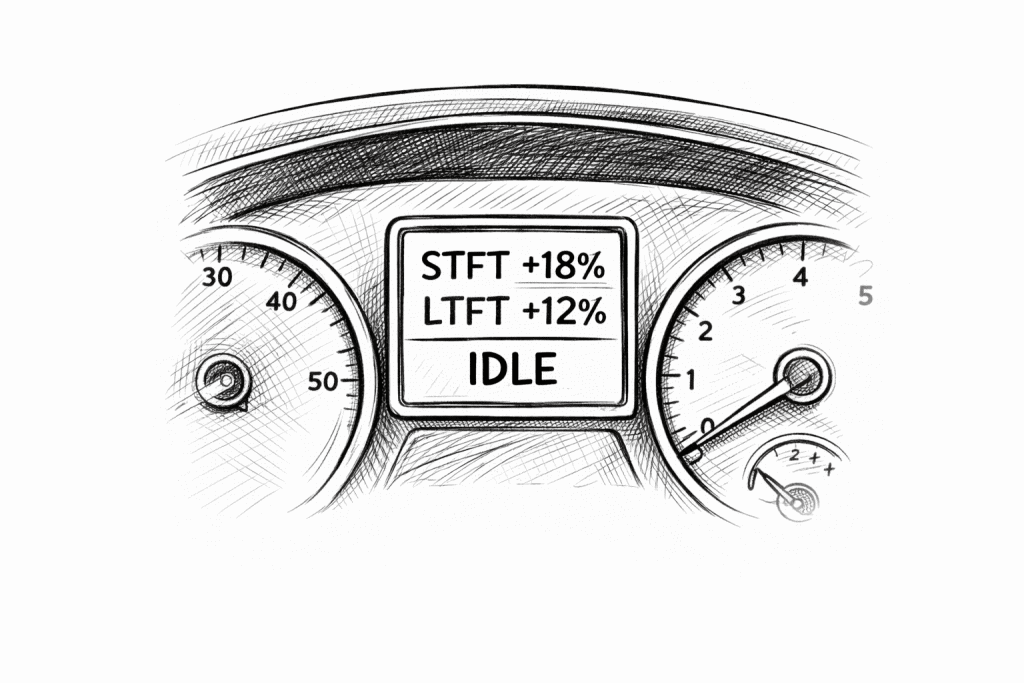

Step 1) Pull codes and look at fuel trims (if you have a scanner)

- Start the engine and let it idle.

- Check:

- STFT (Short-Term Fuel Trim)

- LTFT (Long-Term Fuel Trim)

- A common pattern with vacuum leaks:

- Idle trims are high positive (engine adding fuel)

- Trims improve when revved slightly (because leak becomes a smaller percentage of airflow)

- As a rough rule:

- 0 to +5% is generally healthy

- +10% to +25% suggests a strong lean correction (often vacuum leak or fuel issue)

(Exact thresholds vary by vehicle.)

Step 2) Do a fast visual inspection (most leaks are obvious)

- Engine off. Use a flashlight and follow air/vacuum paths:

- Air intake tube from airbox → MAF → throttle body

- Small hoses from intake manifold to:

- Brake booster

- PCV system

- EVAP purge valve

- Any vacuum reservoir/solenoids

- Look for:

- Split rubber elbows

- Soft, collapsed hoses

- Hoses that slipped off a nipple

- Cracked intake boot (especially on underside)

- Missing clamps

Step 3) Listen for the leak (quick “poor man’s stethoscope”)

With the engine idling:

- Listen around the intake manifold area

- Use a piece of hose as a listening tube (one end near suspected areas, other end at your ear)

A vacuum leak often sounds like:

- Sharp hiss

- Whistle

- Rhythmic sucking noise

Step 4) Check the intake boot and clamps (high-probability fix)

This is one of the most common failures.

- Wiggle the intake boot gently while idling (do not put your hand near belts)

- Look for hidden cracks on the underside

- Tighten loose clamps

If boot is cracked: replace it. Tape is temporary and usually fails quickly from heat/oil.

Step 5) Test the PCV system (very common leak source)

A PCV hose split or a PCV valve/grommet leak creates a direct unmetered air path.

Checks:

- Inspect PCV hose for cracks at ends

- Inspect rubber grommet/O-ring where PCV seats

- If you pinch the PCV hose at idle and the idle changes noticeably, it can indicate a PCV-related leak (results vary by design)

A failing PCV valve or deteriorated PCV hose is one of the most common causes of vacuum leaks. If you suspect the PCV system is involved, follow this step-by-step PCV Valve Replacement Guide to inspect and replace the valve, hose, and sealing grommet correctly.

Add a comment Cancel reply

Comments (0)

PCV Valve Replacement Guide (Step-by-Step) - Flip Cars

[…] How to Fix a Vacuum Leak […]

Categories

- Buyers Guide (4)

- Car Reviews (34)

- Cars (31)

- Depreciation (2)

- Depreciation Calculator (1)

- Fuel Calculator (1)

- Fuel Economy Guides (4)

- Guides (77)

- How To (13)

- Loan Calculator (1)

- Maintenance Cost Calculator (1)

- Maintenance Guides (1)

- Ownership Cost Calculator (1)

- Ownership Guides (2)

- Reliability & Ownership (1)

- Repair Cost Estimator (1)

- Repair Guides (5)

- Safety (1)

- SUV Reviews (33)

- SUVs (33)

- Tools (1)

- Towing & Payload Guides (2)

- Trade-In Value Estimator (1)

- Truck Reviews (7)

- Trucks (7)

- Vehicle News (3)

- Vehicle Research (32)

- Vehicle Reviews (71)

Recent Posts

About us

Related posts

Ignition Coil Replacement: Step-by-Step Repair Guide

Step-By-Step Guide: Spark Plug Replacement

Step‑by‑step guide: Replacing disc brake pads

- Guides

- Vehicle Research

- Tools

- Company

- Buying Guides

- Vehicle Reviews

- Fuel Cost calculator

- About Us

- Maintenance Guides

- Vehicle News

- Maintenance Cost Calculator

- Contact

- Repair Guides

- Towing & Payload Guides

- Repair Cost Estimator

- Privacy

- Ownership Guides

- Fuel Economy Guides

- Ownership Cost Calculator

- Terms

- Depreciation Guides

- Reliability & Ownership

- Trade-In Value Estimator

- Disclaimer

- Depreciation Calculator

- Loan / Payment Calculator